Calcium silicate board as a new green environmental building materials except the traditional gypsum plate of features outside, it has superior fire performances and the resistance tide, sound insulation, fireproof waterproof heat insulation,light weight and so on. It also has the advantage of using long life. The new type of board is widely used in the building of ceiling smallpox and wall, family decoration and so on.we are provide calcium silicate board production Line,we can guarantee quality.

Standard calcium silicate board dimension

Length: 2400-2440mm

Width: 1200-1220mm

Thickness: 4-30mm

We also can produce other sizes as the customer's requirement.

The material and the production process of calcium silicate board

quartz powder, cement, hydrated lime powder, asbestos, paper pulp, wollastonite and others etc.

Calcium silicate board technical parameter

| Item | Unit | Standard Fiber Reinforced Calcium Silicate Board |

| Density | g/cm3 | <1.2 |

| Anti-bend strength | MPa | >9 |

| Heat conduction modulus | w/m.k | <0.29 |

| Anti-impact strength | kJ/mm2 | >2.0 |

| Pull force of screw | N/mm | >75 |

| Dry shrinkage rate | % | <0.2 |

| Non-burn performance |

| In accordance with standard GB8624 First ClassNon-burn Material |

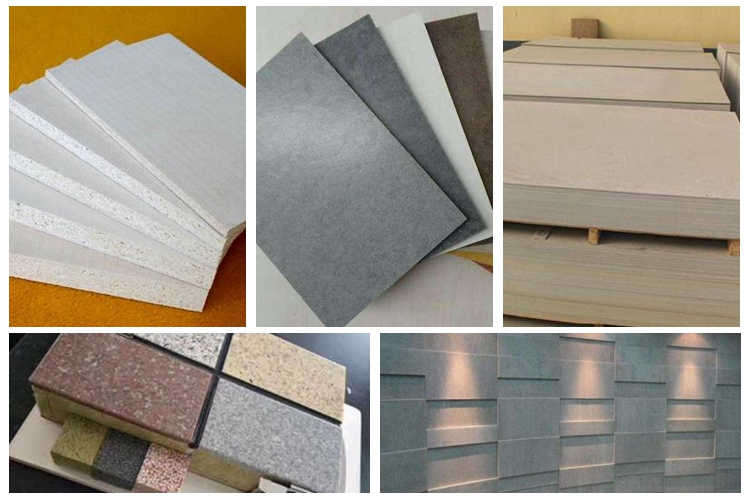

Calcium silicate board application

partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof.

Calcium silicate board products and properties

1. Year output provided:

Million sqm one year 2-8million sqm one year.

2. Main materials:

Silicon materials: quartz powder, diatomite, fly ash, etc.

Calcium materials: hydrated lime powder, cement, calcium carbide mud, etc.

3. The power supply:

A Mechanical and electrical capacity of 700-1200KW or so explosive filling, high and low voltage switch gear.

4. Calcium silicate board main dimension:

standard size: 1220*2440mm 1200*2400mm Thickness: 4-30mm

suspended ceiling: 595*595/600*600/603*603mm

Density: 900-1200kg/m3

Edges: square /beveled

Installation: match with ceiling grids

The production process of calcium silicate board

1. Quartz plasma processing

2. Paper processing

3. Pulping

4. Seperation, mixing and slurry control

5. Molding, answer the billet and stacking

6. Maintenance and stripping

7. Autoclaved maintenance

8. Drying

9. Sanding, edging and chamfering

we are provide calcium silicate board production Line,we can guarantee quality.