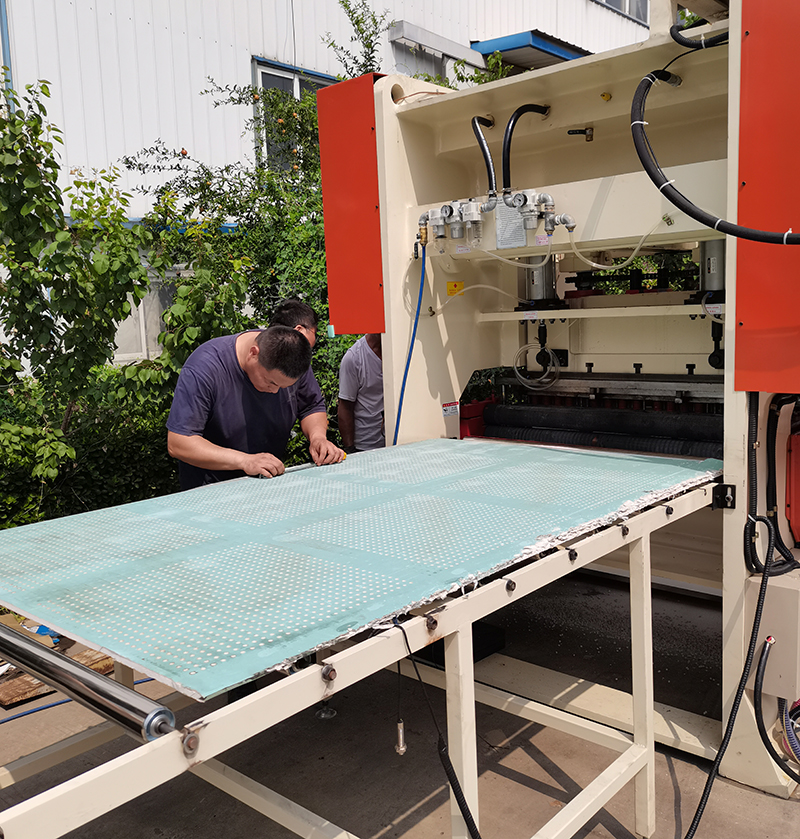

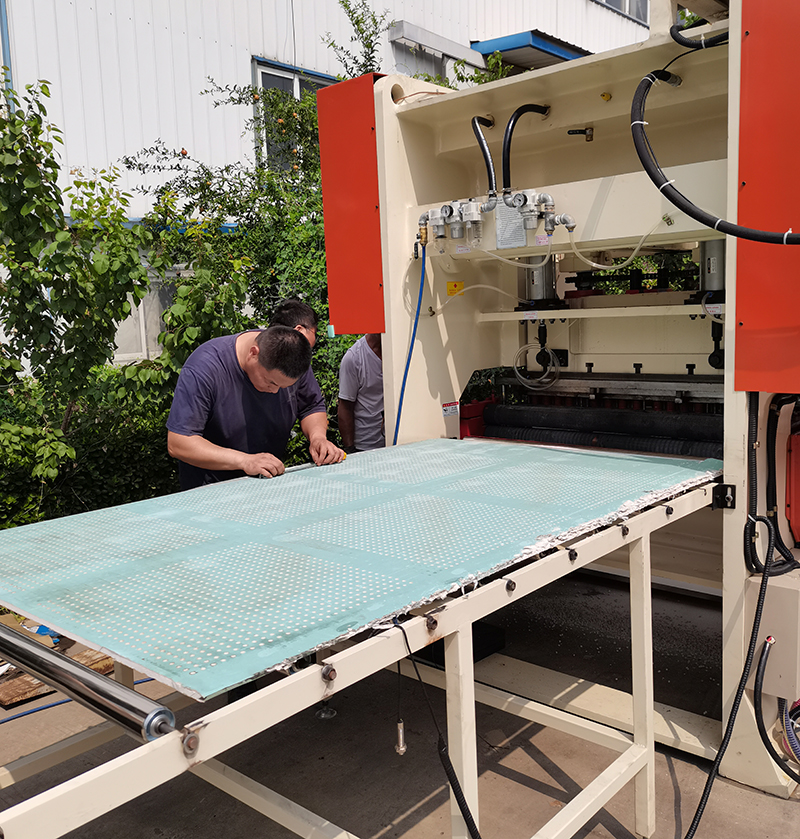

This equipment consists of perforation machine, perforation mold, and a waste collection device.

Gypsum Board Perforationg Machine Features

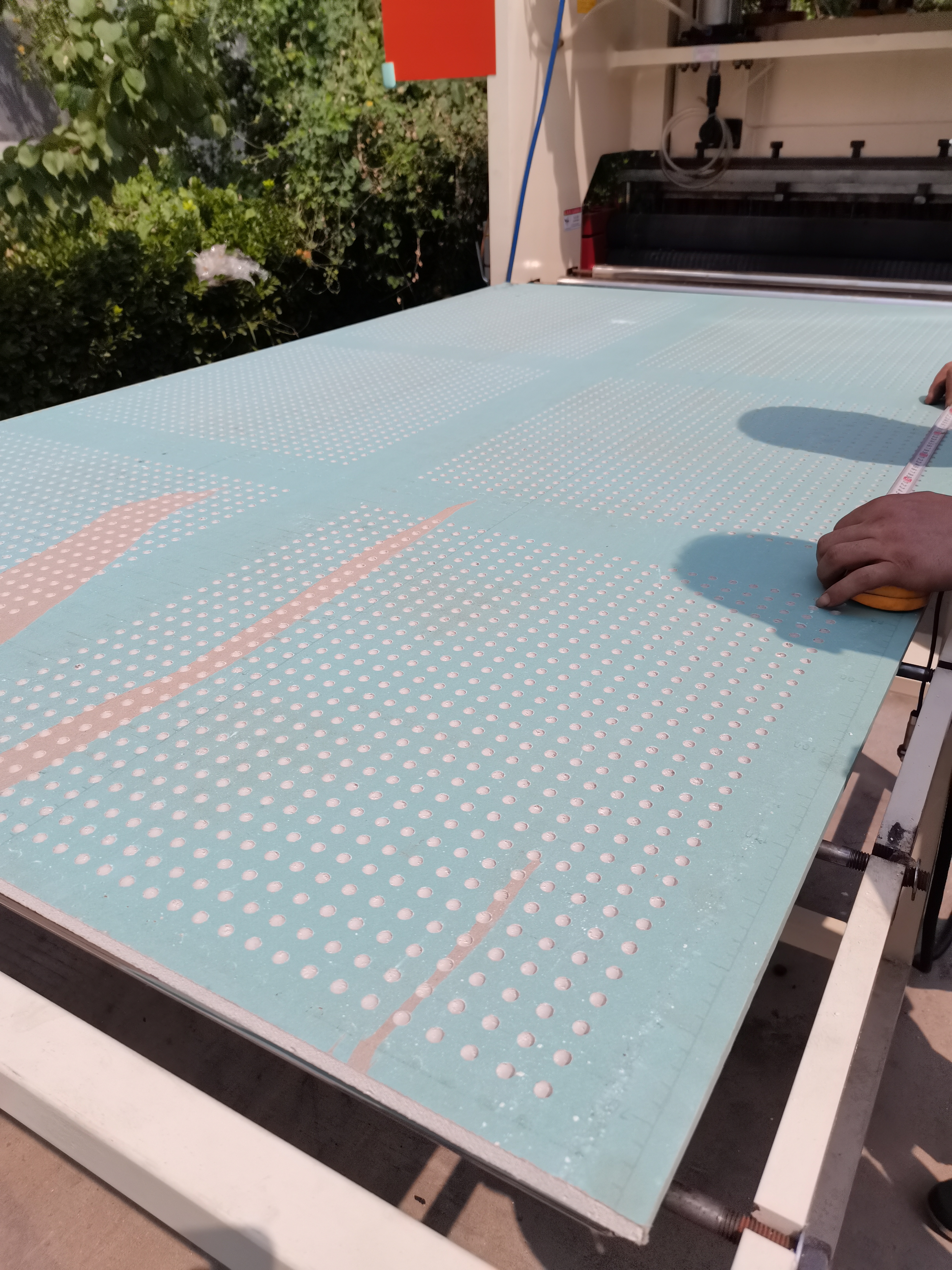

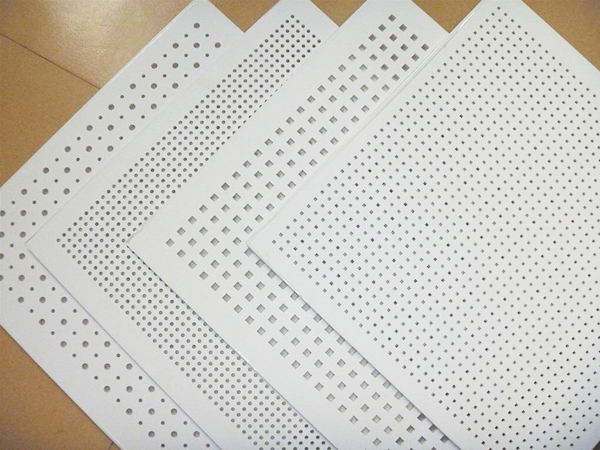

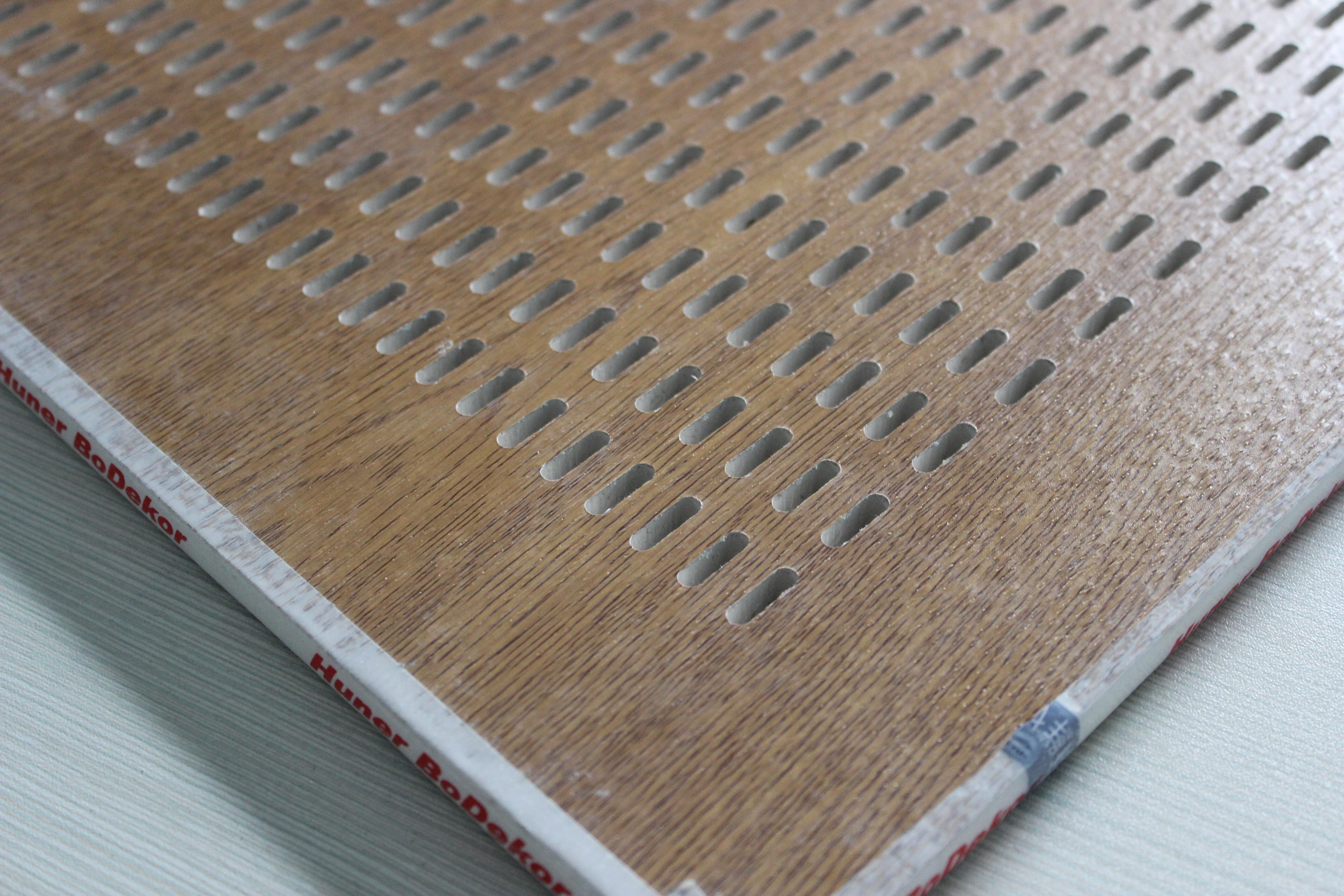

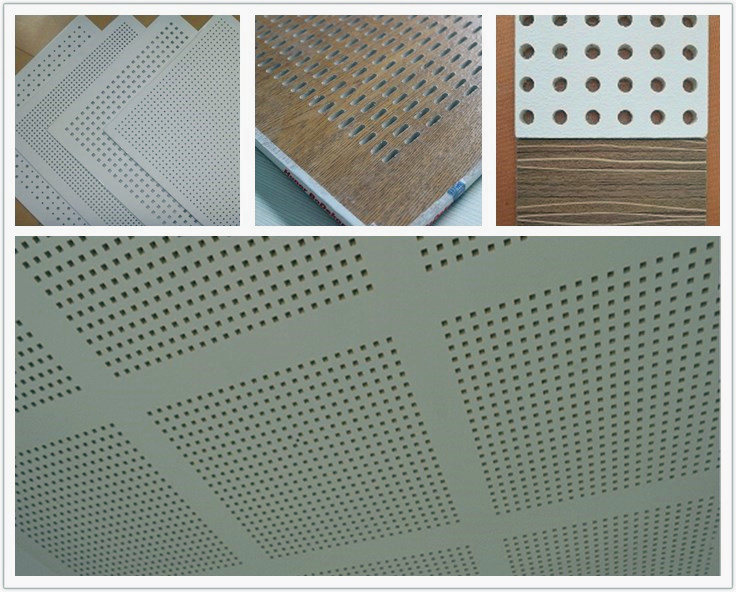

This machine is mainly used for perforating various patterns on gypsum board. It can work on 1220*2440 whole gypsum board, in 2 areas or 8 areas with same mold. At the same time, this machine is also widely used for perforating MDF boards and other boards. The conveyor is controlled by servo motor with high precision.

Main parameters

160 tons pressure Host power 18KW

Gypsum Board Perforationg Machine Perforation Machine

1. Machine Size: 1700x2400x2400mm

2. Certification: ISO9001, SGS, ROHS

This perforation machine is used to perforate holes in the gypsum ceiling board, MgO board, MDF, HDF, Fiber cement board, metal sheet.

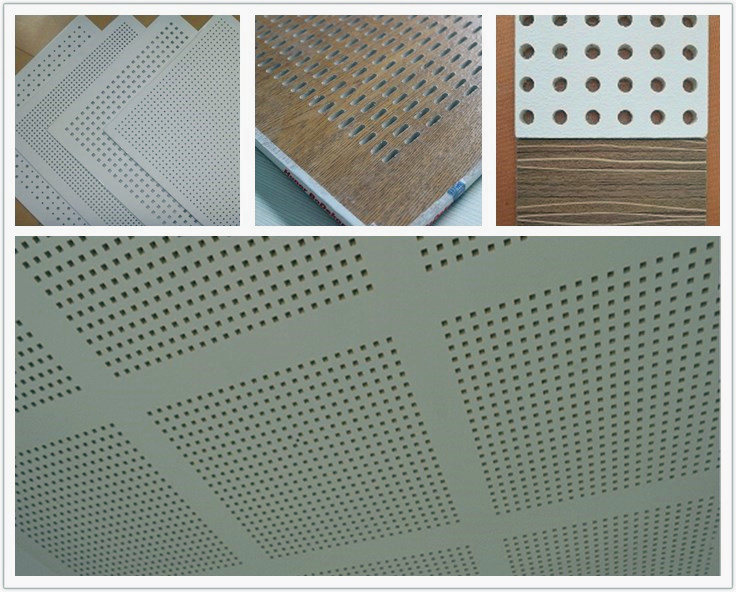

You can choose the shape of the hole as your requirement, about the operation, our worker can teach you how to use it.we are gypsum board perforationg machine for sale,we can guarantee quality,visit us and request a quote today.

| Product Name | Gypsum Board Perforation Machine LVJOE Brand |

| Punching pressure | 160T |

| Punching stroke | 30mm |

| Max gypsum board punching thickness | 20mm |

| Total weight | 7000kg |

| Punching speed | 1 board/m in 50 times/min (1220mm*2400mm) |

| Good effection for perforating | the holes are Smooth, clean, burr, and vertical |

| Suitable Board | gypsum board, calcium silicate board, other |

| Hole shape | long square hole, square hole, round hole,triangle hole, hexagonal hole, the plum blossom hole,ichthyosisthe hole,scale hole and other different kinds of hole |