Product Description: 1. Capacity: 2000pcs/8h-10000pcs/8h 2. Automatic level: high automatic. 3. Raw material: natural gypsum powder, mesh, fiber-glass, water, addtives 4. Installation and commission: 2 workers , 15-20 days.

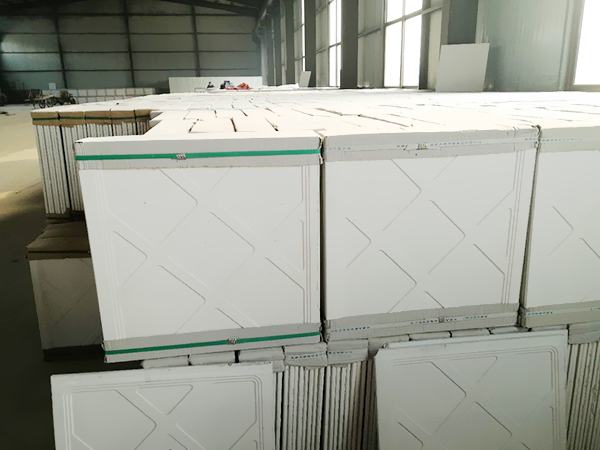

According to different purpose 1. interior wall board 2. exterior wall board 3. floor plate 4. Decorative sheet

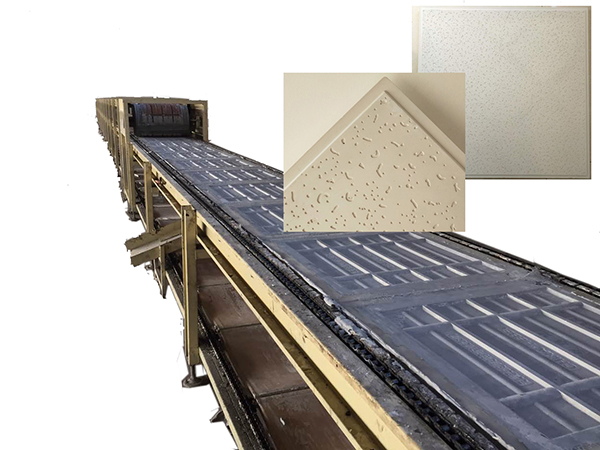

The mineral fiber board production line includes raw material mixing system, fourdrinier forming system and vacuum pump system, water cutting system, accelerating conveying system, lifting distribution system, board feeding system, drying system, hot air circulating system, board releasing system, board over-turning system, puttying system, small drying system I, coating system, small drying system II, embossing system, small drying system III, cutting system, dust collecting system, packing stacking system, control system.

The production of MgO board adopts the wet plate rolling forming process, where the raw materials are measured and weighed through proportioning, mixed and stirred by a mixer (manually or automatically), and rolling forming. Primary curing, demolding and secondary curing in the curing room. Cutting and sanding, quality inspection and packaging. Complete the entire production system. The products are divided into: regular version of MgO board and MgO sanding board.

Our company is the first manufacturer in China to develop and produce automatic PVC gypsum ceiling production line. It has fully automatic production line(single-side lamination type and double side lamination type), semi-automatic production line and economic type for customers to choose. As the production line uses modular combination, we can give appropriate solution according to customer requirement and budget.