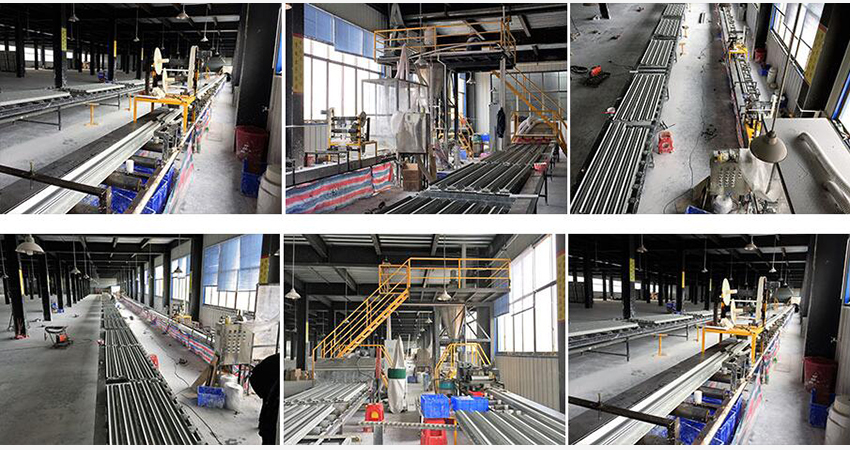

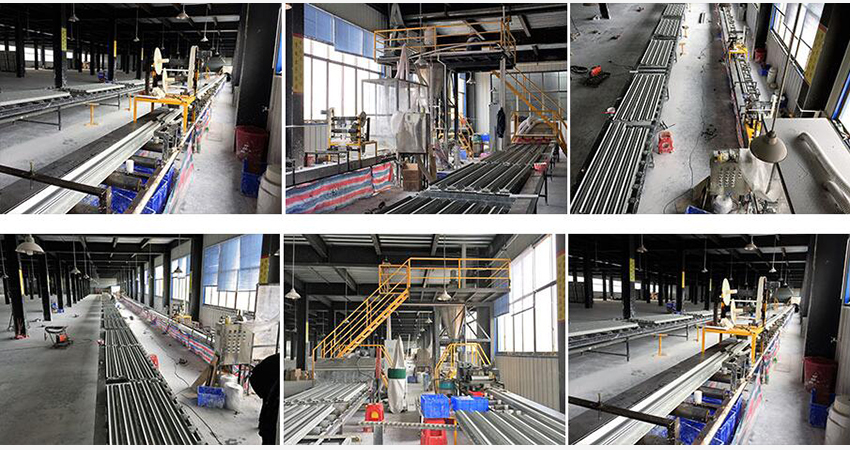

The gypsum cornice machine includes screw conveyor, dry material mixer, wet mixer, roller conveyor

Application

Gypsum cornice belongs to house decorative material and mainly used in indoor decoration. Except fireproof, moisture-proof, soundproof and thermal isolation, it can reach luxurious decoration effect.

Product Description

| Capacity (8hours) | Power (KW) | Equipment length | Workers |

| 2000/pcs | 30 | 42m | 5---6 |

| 3000/pcs | 30 | 48m | 7---8 |

| 4000/pcs | 35 | 54m | 8 |

| 5000/pcs | 35 | 60m | 8 |

| 6000/pcs | 35 | 80m | 8---9 |

| 10000/pcs | 35 | 150m | 12 |

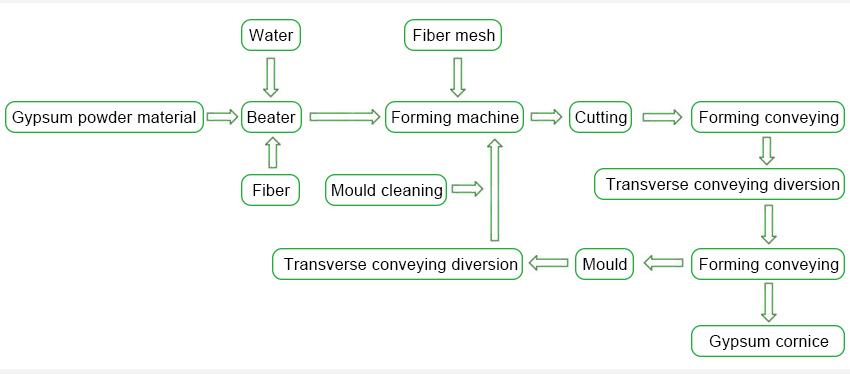

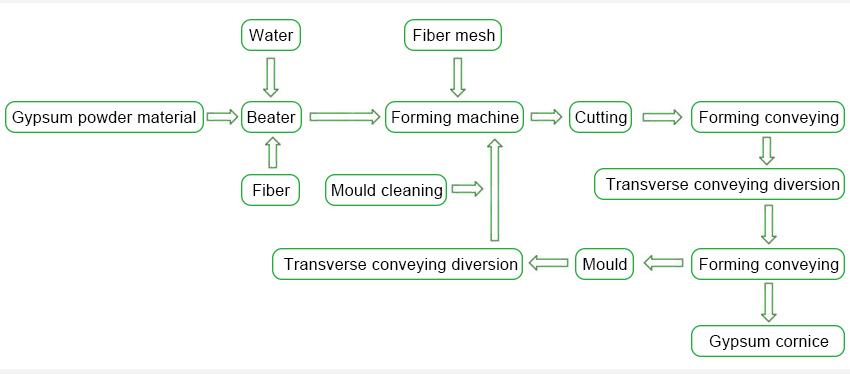

Production process

Application of gypsum cornice

Gypsum cornice is a kind of building decoration material for house, maily for indoor ceiling. It can be with various decorative design,which is artistic with cheap price. Except the function of fire-proof, moisture-proof,sound-proof and heat-isolated, gypsum cornice can reach luxurious decoration effect.we are provide gypsum cornice production line for sale,we can guarantee quality.

Data for gypsum cornice making machine

1. Automatic production line

2. Land area: warehouse design can be adjustable according to clients' situation

3. Raw material: construction gypsum powder, mesh, fiber-glass, water, addtive

Gypsum Cornice Make Machine

Working days per year: 300 days

Working hours per shift: 8 hours/shift

| System | Workers needed |

| Mixing system | 1workers/shift |

| Forming system | 1workers/shift |

| Cosswise transport system | 1worker/1shift |

| Finished product release | 2worker/1shift |

| Finished product drying | 2worker/1shift |

| Maintenance section | 1 worker/1shift |

| Warehouse keeper | 1 worker/1shift |

| Monitor | 1 worker/1shift |

| Total | 10 workers/shift |