XPS extruded board production line is a kind of insulation board made of polystyrene and foaming agent as raw materials, which is extruded at high temperature. At present, HCFC is mainly used as foaming agent in the industry. The potential value of the agent to destroy the ozone layer is relatively large. According to the Montreal Treaty, China has gradually restricted the use of HCFC.

Based on market conditions, our company introduces excellent technology, tailor-made and developed CO2 extruded board equipment for customers. CO2 completely replaces fluoro chlorohydrocarbon foaming agent, and truly realizes the fluorine-free foaming process, creating a precedent for CO2 foaming. According to the various needs of customers, multiple blowing agents can also be shared.

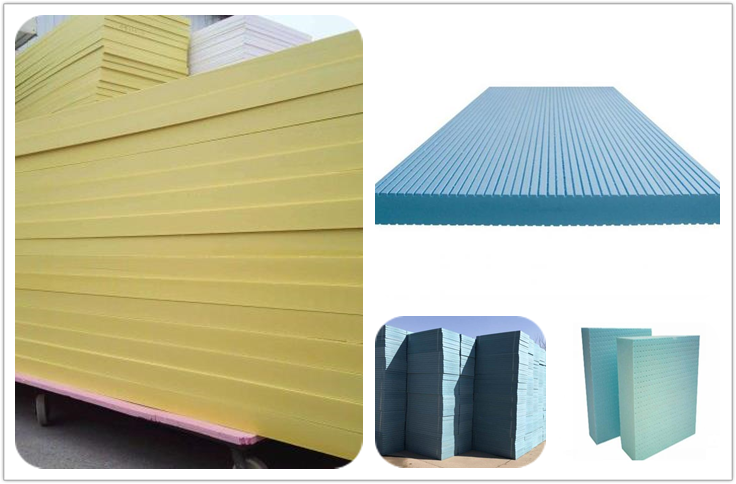

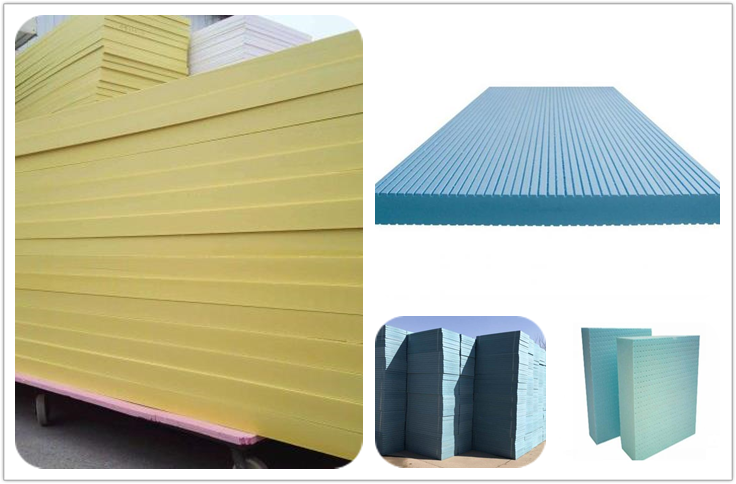

XPS CO2 foam board performance

◆ Flat and even surface, completely closed-cell internal honeycomb structure

◆ Thermal insulation (thermal conductivity 10℃: ≤0.028w/Mk),

Excellent soundproof and moisture resistance

◆ High pressure resistance (pressure: ≥250kpa), light weight (density up to: 28kg/M3)

◆ Non-absorbent (absorbent: ≤1.0%), airtight, wear-resistant and non-degradable

Advantage Of Flame Retardant Effect And Performance Advantages

In order to control the flammability of the extruded board, the method commonly used is to add a flame retardant, and the XPS board produced by adding the flame retardant and melt blended can become a flame retardant XPS extruded board.

Usage of the XPS foam board

It is made of Extruded Polystyrene.This kind of board is widely used for building insulation such as roof, wall and floor insulation.

When the house is installed with the boards, it is just like a thermal barrier. The heat lose can be greatly reduced. It is also an effective guard against the cold and damp.

When used under underfloor heating the board greatly increases the response rate and overall efficiency of all under floor heating systems.