PVC Gypsum Ceiling Tiles Production Line

gypsum board laminating machine manufacturers

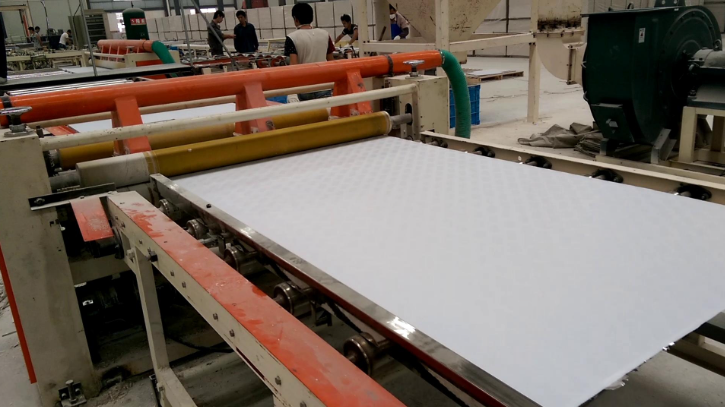

Gypsum Board Laminating Machine Application

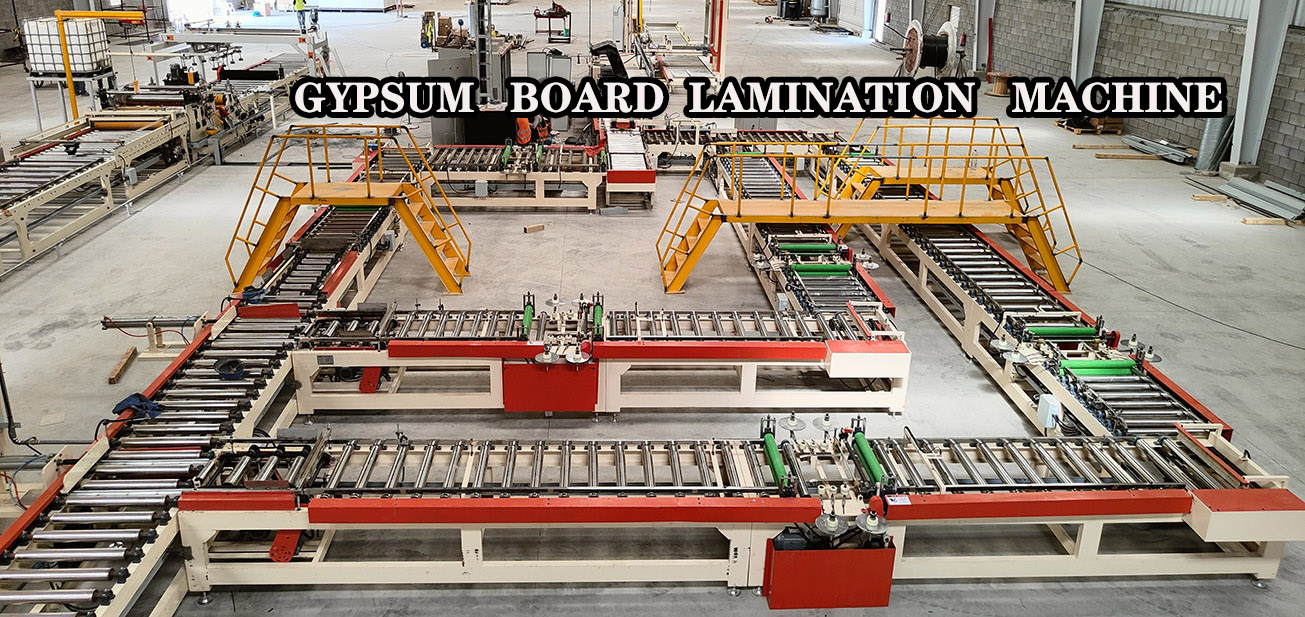

Complete line for Gypsum board laminating with PVC and PET foils

Gypsum Board Laminating Machine ApplicationComplete line for Gypsum board laminating with PVC and PET foilsThe lamination machine is used to paste decorative films like PVC film, aluminum foil etc with board (gypsum board or other board)together. Our latest Technology of full automatic ceiling production line and double side lamination line is very popular in domestic and international market. It is high automatic, saves manpower.

The finished PVC gypsum ceiling tile is made of paper-faced gypsum board with a layer of PVC on surface and aluminum foil on its back. It is a environmental friendly, light weight, high quality, fireproof, waterproof and corrosion-resistant decorative ceiling board. It is easy to clean, and the patterns can be customized. It can be widely used in high fireproof and waterproof requirement environment, such as hotels, restaurants, shopping malls, theaters, stations, auditoriums, offices, living rooms, office buildings, electronic computer rooms, precision instrument rooms, and interior decoration of factories or houses.

Pvc Gypsum Ceiling Tile Size

| Size(mm) | 595*595 *7.0, 7.5 ,8.0 |

| 603*603 *7.0, 7.5, 8.0 |

| 600*1200 *7.0, 7.5, 8.0 |

Gypsum Board Laminating Machine Features

1. Different automatic levels for your choice.

2. Adopting world famous brand Siemens PLC control system.

3. High capacity of 2-6 million sqm per year.

4. Raw materials: Gypsum board, PVC film, Aluminum foil, glue

5. Effective laminating width: Max 1300mm

6. Sheet thickness: 5--30mm

7. Laminating speed: Max 15m/min

8. Speed adjust way: frequency conversion synchronous speed regulating

9. Certification: ISO9001, SGS, CE

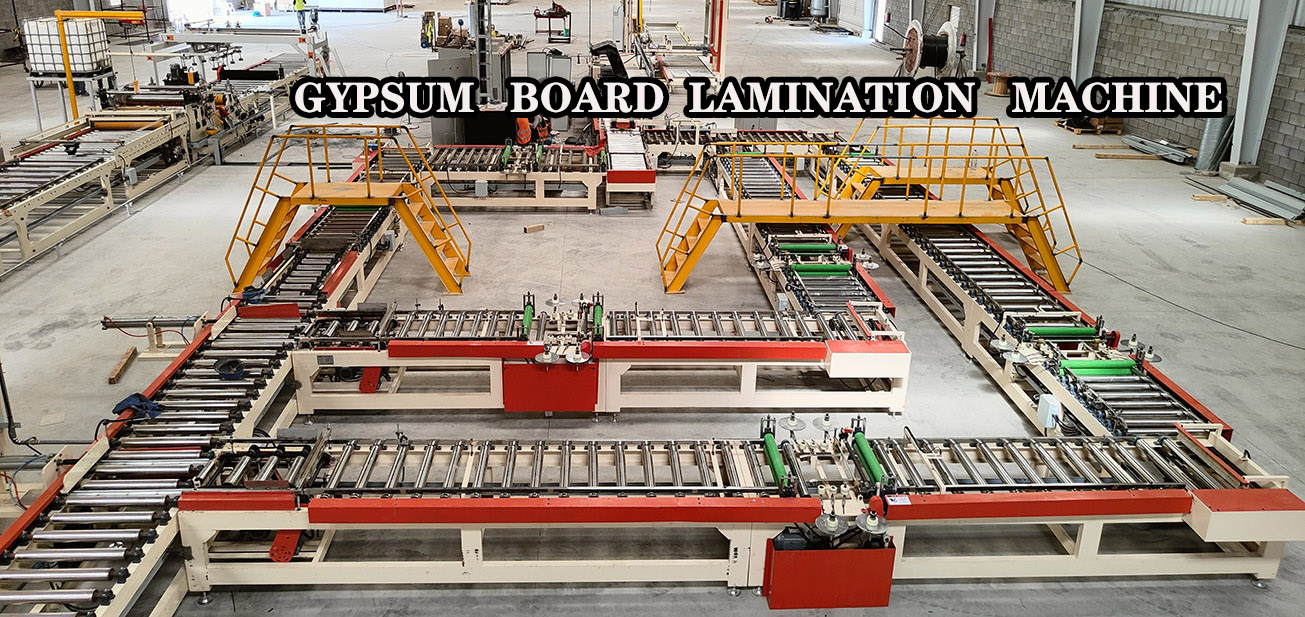

The Full Laminating Line includes the following machines

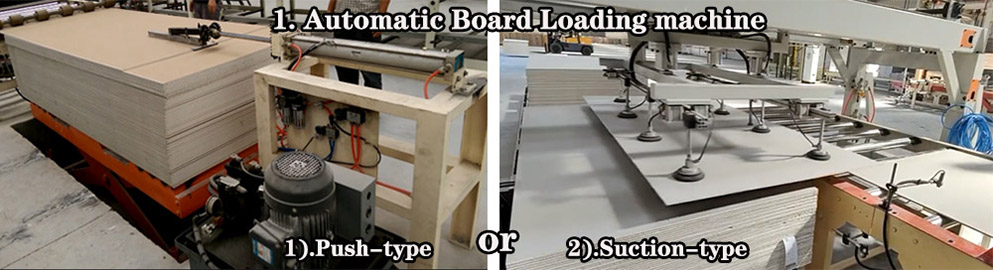

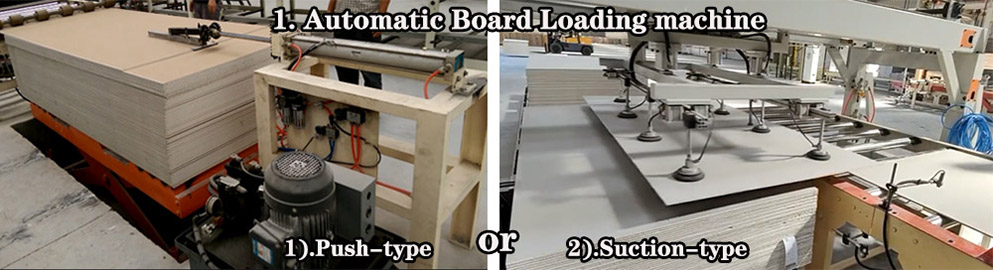

1. Automatic Board Loading machine

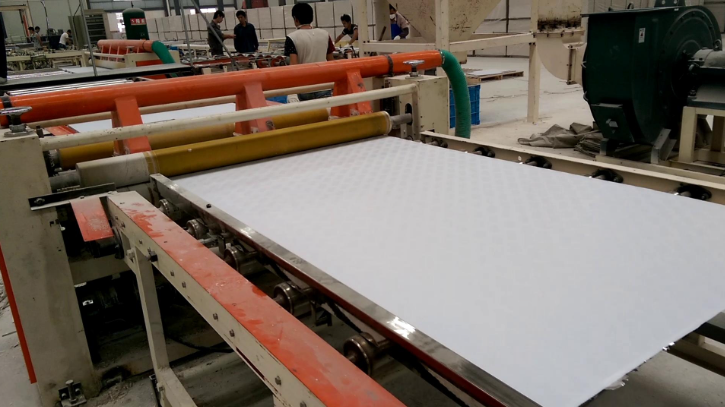

2. PVC film and Aluminum foil laminating machine(Double sided)

3. Cutting machine

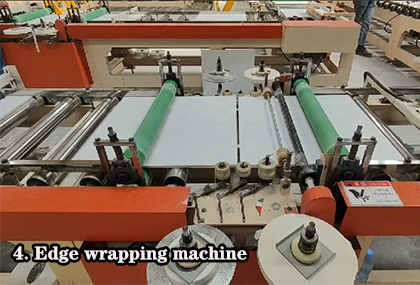

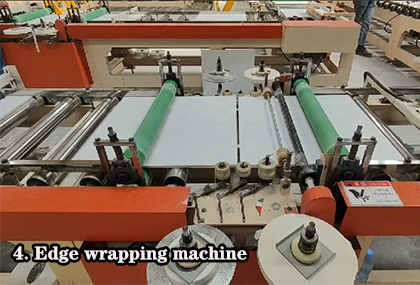

4. Edge wrapping machine

5. Packing machine

6. Finished board stacking