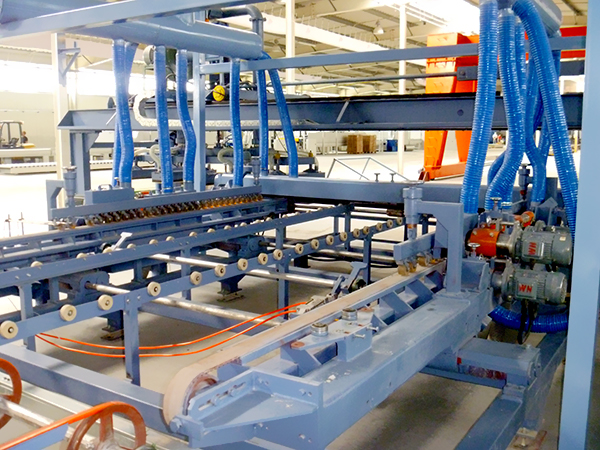

fiber cement board making machine(fiber cement board production line) is a new kind of green building material, in accordance with the national building material industry standard. Fiber cement board belongs to non asbestos and asbestos fiber cement board. At present in domestic fiber cement board is mainly non asbestos fiber cement board. The main material are the fiber( serpentine asbestos),cement(Portland cement), silica power and other additional materials. The whole process used special production craft, after pulping, copy, pressurized and four curing procedure. It is widely used in various fields of the construction industry.

The Classification of fiber cement board:

According to the thickness

1. super thin slab: 2.5-3.5mm;

2. standard board: 4-12mm;

3. thick board: 12-30mm;

4. super thick board: 31-100mm。

According to different purpose

1. interior wall board

2. exterior wall board

3. floor plate

4. Decorative sheet

According to whether add asbestos

1. chrysotile fiber cement board

2. Non asbestos fiber cement board

The performance of fiber cement board

1. Fire insulation: incombustible A1 level, do not produce poisonous gas, coefficient is low.

2. Waterproof: it is suitable for bathroom, swimming pool, underground passage,etc.

3. Anti-corrosive, anti-insect: high corrosion resistance, no rust, not afraid of mosquito bite.

4. Noise insulation: high density, good sound insulation, low thermal conductivity, heat preservation performance is good.

5. Light weight: high strength, light weight, not burst, constant folding, high shock resistance.

6. Safe non-toxic: non-radioactive, accord with the “national construction material radioactive protection standard”

7. Can be processed and secondary decorate good performance: can cutting, drilling, engraving , paste.

Fiber cement board application

1. Fiber cement pressure plate used in indoor partition has the characteristics of waterproof\fireproof\the better sound insulation than the gypsum board and calcium silicate board. But because of the high investment, it mainly used in the high-grade facilities such as hotel\Guesthouse\ Villas and National stadium.

2. Fiber cement pressure plate used in exterior wall cladding is similar with the stone. Compared with the huge price of stone especially imported stone,fiber cement pressure plate has been increasingly used in all kinds of buildings such as many venues of the World Expo and the Asian Games.

3. External wall insulation board: For energy-saving considerations, many building in North China were designed in the external wall thermal insulation. It is more common to use fiber cement pressure plate and extruded sheet as the external wall insulation board.

4. With the rise in price, dual structure of the residential area are unfolding in all parts of the country. The use of fiber cement floor has the more advantages than the traditional density board (wood) such as water-proof and moisture-resistant, fire insulation, corrosion resistant insects etc.

5. Fiber cement pressure plate also widely used in high speed railway sound barrier\electrical insulating board\wall lining and other fields.we are provide fiber cement board production line(fiber cement board making machine),we can guarantee quality.,we can guarantee quality.

fiber cement board production line(fiber cement board making machine)

Fiber cement board application