fiber cement board making pressure plate performance

1,fire insulation: non-combustible A1 grade, does not produce toxic gases; low conductivity.

2,waterproof and moisture-proof: not afraid of water, not afraid of wet, more suitable for bathrooms, swimming pools, underground passages, etc.

3,anti-corrosion and pest control: high corrosion resistance, no rust, not afraid of mosquito bites.

4,sound insulation: high density, good sound insulation; low thermal conductivity, good thermal insulation performance.

5,light and high strength: high strength, light weight, no cracking, constant folding, high impact resistance. 6, safe and harmless: non-toxic, non-radioactive, in line with the national "standards for radioactive protection of building materials."we are provide fiber cement board making machine,we can guarantee quality.

7,can be processed and secondary decoration performance: free to cut, drill, engrave, paste as needed. The performance of fiber cement pressure plates.

History of fiber cement board

In 1900, the Austrian Ludwig Hatschek invented the use of rotary netting to make fiber cement boards;

Commercial production of fiber cement board began in 1905, starting with the MD/LD series;

After more than 100 years of exploration, improvement and innovation in this production technology in different countries, different research institutes and different scientists all over the world, today's fiber reinforced cement products have played an extremely important role in building materials. important role.

Production technology is derived from the “copying method”: new production technologies such as “flowing method” and “casting method”; cementitious materials have also experienced from single cement to sandy cement, synthetic calcium silicate, etc.; From the initial paper fiber development: asbestos, brucite, sepiolite, glass fiber to wood pulp fiber.

Production technology is becoming more and more mature, product quality is more and more stable, and performance is getting higher and higher. In the 1980s, the former Fujian Sanming Factory established the first fiber cement board production line in China.

The role of fiber:

From the mechanical point of view, the fibers uniformly dispersed in the cement stone prevent and delay the development of fine cracks in the cement stone. When large cracks appear in the cement stone, the fiber provides tensile stress. Cement acts to transfer stress and cement fibers.

The effect of fiber is similar to that of reinforced concrete, but there is a big difference between the two theories applied in mechanical analysis. The steel is mainly used in the tension zone of concrete, which is concentrated reinforcement;

The fiber is a large amount of dispersive reinforcement of broken fiber, which has different effects on product performance and strength analysis.

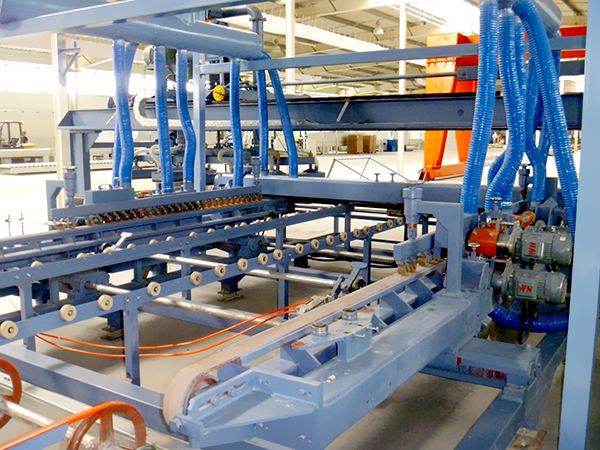

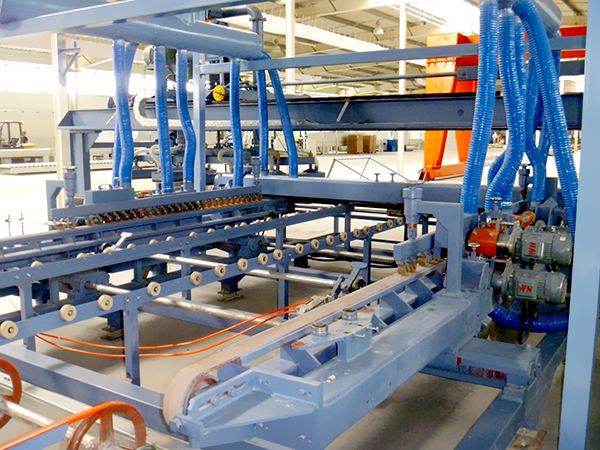

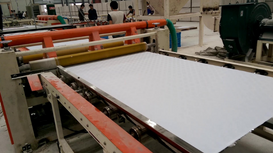

Main process:

It adopts the latest international SBS method (combination of slurry method and copying method) to produce. In addition to the usual fiber cement product process, it must be pressurized and autoclaved.

Autoclaved curing is a method of curing products with high water vapor pressure. Steam curing can reduce consumption, reduce raw material cost, shorten production cycle, improve wear resistance, and exert good strength and shrinkage deformation.we are provide fiber cement board making machine,we can guarantee quality.

Development trend of building boards:

China's construction sheet production has maintained a rapid growth rate (10-40%) from 1993 to 2006.

Since 2002, the number of manufacturers of cement fiberboard or calcium silicate board has increased, and the development of sheet has begun to take shape. In 2006, the output of fiber cement board/calcium silicate board was about 200 million m2.