What is the difference between carbon dioxide extruded board and ordinary extruded board?

What is carbon dioxide extruded board?

Just as steamed buns need yeast for foaming, the production of extruded board also needs foaming agents to foam. There are many kinds of traditional extruded board foaming agents, such as HCFCs (freon), butane, ethanol, dimethyl ether, liquefied petroleum gas, etc.

Carbon dioxide extruded board refers to an extruded board produced with carbon dioxide (CO) as the main blowing agent.

Figure 1 ▲ Continuously breaking extruded board

Because freon foaming is easier to control, traditional extruded boards basically use freon as the main foaming agent. Liquefied petroleum gas is also useful because it is cheap.

However, Freon is not environmentally friendly, and LPG is too dangerous.

Since the release of the Montreal Protocol, China’s extrusion industry has been actively exploring the use of more environmentally friendly carbon dioxide instead of Freon as a blowing agent.

Carbon dioxide foaming has high requirements for production lines and production technology, and now there are few companies that have mature technologies. Therefore, carbon dioxide extruded panels are considered delicious in the market.

What are the differences between carbon dioxide extruded board and ordinary extruded board?

We found several extruded boards with a density of 33-35Kg/m for comparison. From the naked eye, we can find several differences.

First, the cross-section crystal reflects less light

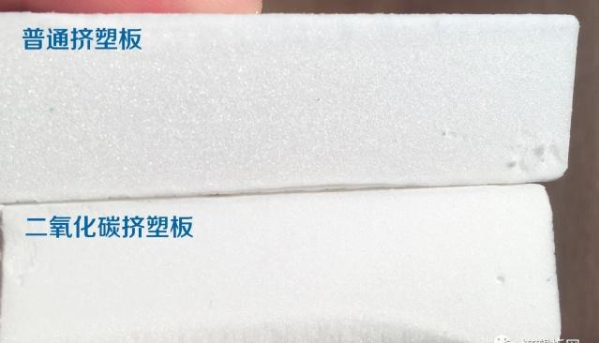

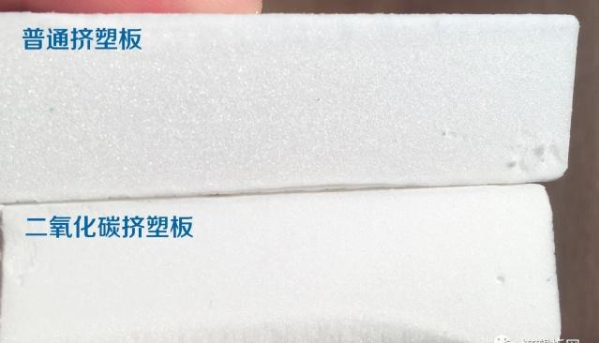

Figure 2 ▲ Comparison of cut sections

As you can see from the picture above, the crystals of ordinary extruded panels reflect more light.

Figure 3 ▲ Comparison of Banbreaking Section

As can be seen from the above picture, the crystals of ordinary extruded panels reflect more light, and the cross section of the breaking section is very flat, and the cross section of the carbon dioxide extruded panel is uneven and striped.

If you look closely, you can see that it is the cell wall of the extruded sheet that reflects light. Because the cells are large, the reflection of the cell walls is obvious and visible to the naked eye.

No crystal reflection, indicating that the cells of the carbon dioxide extruded board are more delicate.

Second, the hand feel has low hardness

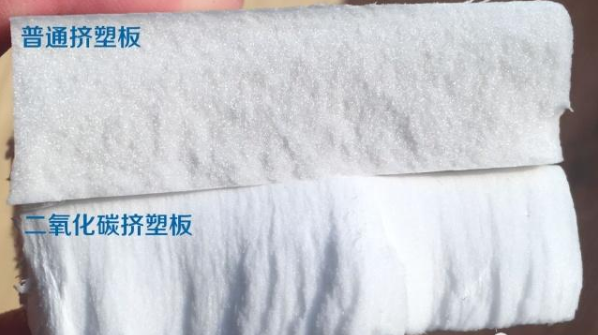

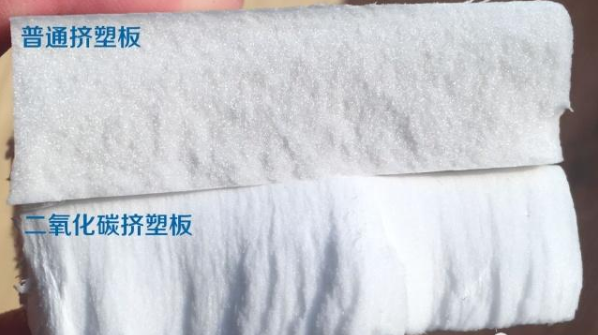

Figure 4 ▲ Comparison of skin thickness

As can be seen from the above figure, after pressing hard, both extruded boards will be concave, and the surface of ordinary extruded boards will break.

Note: Hand-feel hardness does not represent compressive performance, the hand feels only the hardness of the skin.

This shows that the ordinary extruded board has a thicker skin and high brittleness. The surface of the extruded board has basically no cells, so it has no heat preservation effect, and it is easy to sink once it breaks.

The carbon dioxide extruded board has low hand feel and hardness, which means that the skin is thinner and the heat preservation is better; it will not sag after pressing, which means that the cell structure is more stable.

Third, it is not easy to break

Video 1 ▲Comparison of flexibility of extruded board

As can be seen from the above video, the carbon dioxide extruded board has better flexibility, is not easy to be broken, and has an uneven section.

From the production process analysis:

The pressure in the carbon dioxide foaming process is greater, so the pressure difference will be greater when the pressure is released by extrusion. This requires better polystyrene raw materials and more complete molecular chains. Otherwise, the cell wall will be broken and the board surface will collapse.

Figure 5▲Extruded board skin

From the analysis of the extruded board structure:

Ordinary extruded board has a thick skin, and the hardness and toughness of the board depend on the skin. Just scratch the skin during construction and break it lightly.

The carbon dioxide extruded board has a thin skin, and its compressive toughness depends on the stability of all the cells. Therefore, the blade needs to be cut through during construction to break.

It is not easy to break and the section is striped, indicating that the carbon dioxide extruded board has better raw materials and complete molecular chains.

Fourth, the color is relatively light

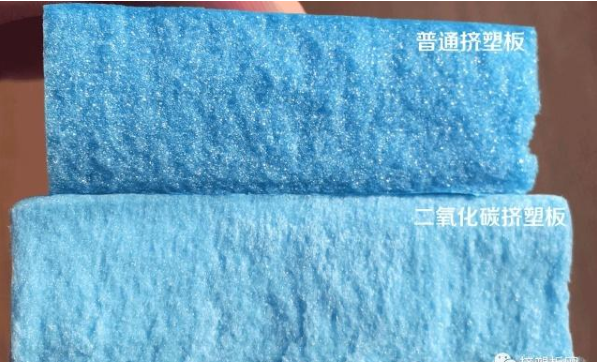

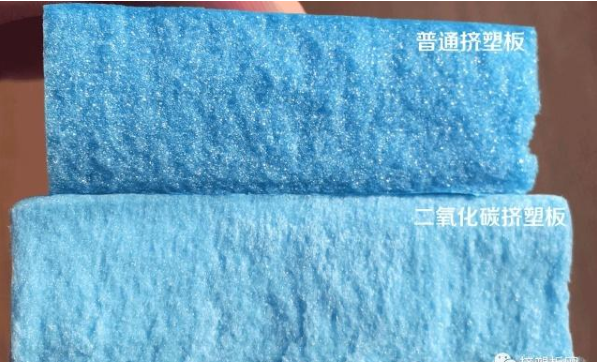

Figure 6 ▲ Surface color contrast

Figure 7 ▲ Sectional color contrast

In the case of the same color masterbatch ratio, the color of the carbon dioxide extruded board is lighter.

Note: It is not to say that the carbon dioxide extruded board is the light color.

Fifth, thermal conductivity analysis

Extruded board is a kind of organic insulation material commonly used in construction. As a building insulation material, it needs to meet several conditions.

First of all, good thermal insulation performance (low thermal conductivity, fine cells), and long-term thermal insulation performance (low water absorption, good weather resistance, long life). Secondly, there are different requirements for pressure resistance (high density, dense cell, and cell wall thickness) due to different application ranges.

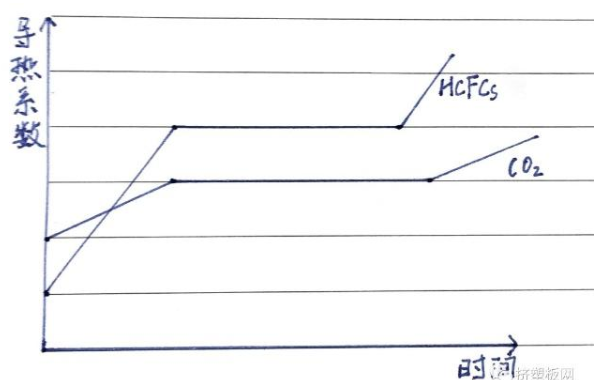

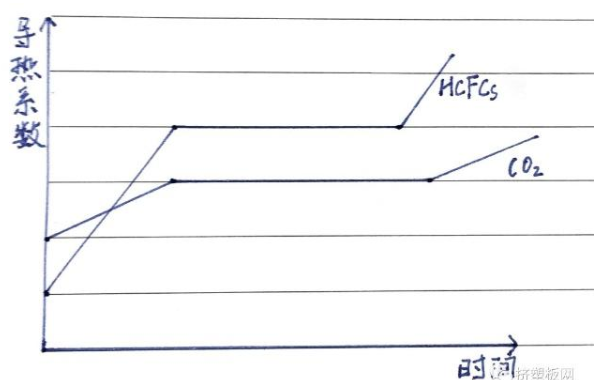

Figure 8 ▲ Comparison of thermal conductivity

As shown above:

The first stage: Because the thermal conductivity of HCFCs is lower than that of carbon dioxide, the thermal conductivity of the carbon dioxide extruded board is higher for the newly produced plates.

At 0℃, the thermal conductivity of HCFCs is 0.011W/(m·K), the thermal conductivity of carbon dioxide is 0.015W/(m·K), and the thermal conductivity of air is 0.024W/(m·K).

The second stage: During the "curing" process of the extruded board, the foaming agent will be replaced with air. Finally, there is only air in the cells of the extruded board. Three months after the offline, the replacement was the strongest. Therefore, after the extruded board is off the assembly line, the thermal conductivity increases slowly.

The third stage: After the "curing" is basically completed, the thermal conductivity of the extruded board will be generally stable after 40-50 years of use. At this stage, the cells of the carbon dioxide extruded board are more delicate and the molecular chain is complete. Therefore, the long-term insulation performance is better and the life span is longer.

The fourth stage: Finally, when the life is reached, the cells are slowly destroyed, and the thermal conductivity will continue to increase.

The compressive strength curve of extruded board is also similar, except that the first and second stages are about 2 weeks, and the fourth stage is the continuous decrease in compressive strength.

summary:

Carbon dioxide extruded board has no crystal reflection, it is not easy to break, the section is uneven, the skin is thinner, and the color is lighter.

The performance analysis of carbon dioxide extruded board is as follows:

1. Carbon dioxide is more environmentally friendly;

2. Thin skin, more outstanding heat preservation performance;

3. Made of new materials, good toughness and long life;

4. The cell structure is more stable without sinking when pressed;

4. The cells are more delicate and the long-term insulation performance is better;

5. The hole wall bears high pressure and can be made into special ultra-high pressure-resistant extruded plastic board.