When purchasing the production equipment of glass magnesium board and fire board, the following factors need to be considered:

1.The glass magnesium board production equipment has basic configuration and fully automated configuration. When purchasing the glass magnesium plate production equipment, the whole production line is selected according to its own comprehensive conditions, mainly based on labor, or computer control. It is a semi-automatic device or a fully automatic device.

2,to see the degree of mechanization of the production equipment of glass magnesium board. Looking at a complete set of equipment requires several people to operate and the labor intensity of the operator. Whether manual handling, manual feeding, manual application, artificial straw are required.

3.If the production of cement foam insulation board, mainly depends on the degree of precision of the equipment, whether it can automatically feed, automatically measure, automatically adjust the thickness and the quality of the finished product.

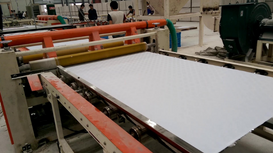

The automated glass magnesium board production line is divided into basic configuration, semi-automatic configuration and fully automatic configuration. The fully automated configuration includes a fully automatic glass magnesium sheet forming system, a fully automatic cutting system, a fully automatic upper formwork system, and a fully automatic plate system.

It has completely changed the situation that the workers of glass magnesium board production have high labor intensity, labor, process and low efficiency. The purchase of glass magnesium board equipment provides free installation and debugging of glass magnesium board technology formula free of charge, guiding customers to produce satisfactory glass magnesium board, Flue board, roofing board.

The glass magnesium fireproof board equipment is mainly used with raw materials:

Rural surplus crop straw or sawdust, magnesium oxide, magnesium chloride, non-woven fabric, fiberglass cloth, perlite and so on.

Glass magnesium fireproof board equipment production process:

Ingredients → Paddle → Drilling → Plate Making → Maintenance → Demoulding → Maintenance → Cutting → Dust Removal → Plate Selection → Packaging → Factory.

4.Advantages of glass magnesium fireproof board equipment: Unique body design, independent adjustment of sections, to meet the horizontal position of production line installation, high strength, high precision, stable transmission, guarantee for continuous large-scale production; use four-roller double drive roller Pressing technology, automatic feeding, hanging, spreading, re-compression, cutting, continuous production and multi-function integration, saving labor costs; equipped with double vibration device, eliminating internal bubbles, making the plate more dense and smooth; conveying table The use of rolling bearings, smooth delivery, small transmission friction, tailored conveyor flat belt, smooth delivery, no slip, no deviation, durable;

The polymer processing roll forming surface is smooth, wear-resistant and resistant to rust. Any adjustment of the upper and lower rollers can produce plates of various thicknesses, thickness 3~40mm, width 1.3m, unlimited length, to meet different market demands; stepless frequency conversion motor, advanced program control, adjustable speed, operation Simple, easy to maintain, the production capacity is as high as 7.25m / min.we are provide mgo board production line and fiber cement board production line,you can know it.

The glass magnesium fireproof board equipment is multi-purpose, and can produce fireproof decorative board, fire door core board, glazed wave tile, light partition board, logistics tray, exterior wall insulation board and the like.

Over the years, our company has always adhered to the principle of technology and customer first, and strives to create a “one-stop, one-stop” service for the trainees. For those who purchase equipment, the company provides relevant technical training free of charge and provides free lifetime after-sales technical services. To enable the students to bypass the detours that the producers in the same industry have gone through, limit the risks and generate investment profits as soon as possible.

company culture:

Entrepreneurial spirit: the courage to learn and innovate, the courage to sacrifice, the courage to take responsibility

Core Values: Establishing a company for the public

Management philosophy: command zero mistakes, zero defects in quality, zero safety accidents.

Humanistic concept: entering the company door is a family

Corporate style: Heavenly rewards, excellence, and seeking truth from facts.