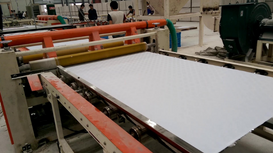

mgo board production line manufacturing process

The glass magnesium plate is based on selected high-quality magnesia and magnesium chloride, and is made of alkali-resistant fiberglass cloth. It is toughened by high-quality plant fiber, using scientific formula ratio, accurately measuring ingredients, mixing and mixing, physical multiple Foaming, room temperature maintenance, high temperature water control, precision yarn cutting, satisfactory process, severe quality inspection, and high quality fireproof board are the green building materials recommended by the National Decoration and Decoration Association.

The data components are high-purity magnesium oxide, high-quality magnesium chloride, alkali-resistant glass fiber cloth, plant fiber with excellent flexibility, incombustible light perlite, chemical stability, and high molecular polymer. The selection of the materials is half of the quality product wins.

Excellent fireproof glass magnesium board has excellent fireproof function, is non-combustible sheet, flame continues to burn time is zero, 800 °C does not burn, no fire at 1200 °C, arrives at the highest fire non-combustible grade A1, and the interval system made of high quality keel, fire resistance limit More than 3 hours, in the process of burning in the fire can absorb a lot of heat, delaying the rise of ambient temperature.

Waterproof and moisture proof In dry and cold climate, the function of glass magnesium board has been stable and stable. It is not affected by condensed water drops and humid air. Even after being soaked in water for several days, it will be naturally dried and will not be deformed or softened. It can be used normally. There will never be a phenomenon of moisture absorption and reflux.

After testing, the board body is not water permeable. The apparent density of the light and shock-resistant glass magnesium plate is 0.8-1.2g/cm3, which reduces the construction load and reduces the weight of the built-in inner wall by more than 60%, and increases the application area by 5-8%. Light weight is conducive to the construction of earthquake resistance, useful to reduce the cost of the base and structural body.

The strength is superior to magnesite special 5.1.8 phase, full of fiberglass cloth and excellent plant fiber. The weight of glass magnesium plate is light, but the structure is strict, the stability is good, it is not deformed, and it has wood-like resistance. It has excellent performance in impact, compression, tensile and anti-fracture functions. Its toughness is biased, and the flexural strength reaches 322kgf/cm2 (straight) and 216kgf/cm2 (degree), and the impact strength can reach 25MPa.

The glass magnesium board is absolutely free of asbestos, formaldehyde, benzene and harmful radioactive elements. It is smoke-free, non-toxic and has no odor. The produced materials are natural mineral powder and plant fiber. The production process is natural maintenance, low energy consumption, no sewage, energy saving and environmental protection. When used, the board surface does not contain powder. The common natural pore structure can adjust the indoor temperature. Make the living room and office more welcoming.

Insulation and energy saving average pore size, dense, inorganic material characteristics, thermal conductivity of 0.216w / cm · k, more insulation than the 1.1w / cm · k of lime sand masonry cut, saving energy consumption, so that the room is warm Environment, refreshing air. Affordable high-quality high-grade glass magnesium plate, the quality is stable and reliable, compared with other glass magnesium plates, has the ultimate cost performance, light weight and high energy, moderate price, excellent processing equipment, can be attached, cut, nailed, drilled, painted, planed, transfer convenient Excellent patience, not easy to crack, use self-tapping screws, gun nails and straight nails to stop light equipment, and use wet and dry hanging operations.

The soundproofing and stability of the glass magnesium board is superior to the sound insulation function, ensuring a quiet and elegant living environment. The light weight of the thin plate does not affect the sound insulation function of the glass magnesium plate. The sound insulation of the 6mm thick plate is 29dB, and the air acoustic sound insulation of the double-sided single-layer 9mm glass magnesium plate + 75 keel + 50 rock wool interval system is greater than 42dB. The pore structure is incomparable to other densely constructed glass magnesium plates.

The common lubrication and rough surface of the multi-purpose glass magnesium plate provide customers with a variety of utility functions. Lubricating surface can be wallpapered, aluminum-plastic board, veneer fireproof board, veneer, PVC, sprayable paint or latex paint; rough surface can be tiled, marble, granite, ash and latex paint.

The glass magnesium plate has excellent affinity for the above data, and can be used for secondary processing on the spot, or can be used twice, and can stop the bending of 30cm in diameter and the physical function is not lost. Durable: scientific formula thoroughly disposes of the problem of moisture absorption and return of magnesite, its strength increases with time, can resist corrosion, acid and alkali resistance, small expansion and contraction, shrinkage rate ≤0.3%, wet The expansion ratio is ≤0.6%, and it has a freeze resistance of -40 °C. After ten years of testing, the glass magnesium board is durable, resistant to aging and has a long life.we are provide mgo board production line and fiber cement board production line,you can know it.

The company implements management in strict accordance with the modern enterprise system, and is committed to advocating corporate advanced culture and strengthening the talent team.

Wu Jianshe creates a good atmosphere of positive, honest, realistic, harmonious and harmonious. The company will be "continuously surpassing itself" as its goal, in the spirit of "unity, integrity, dedication, truth-seeking"

Spirit, in accordance with the sustainable development of science and technology, environmental protection and energy conservation

Exhibition requirements, increase innovation, and constantly develop and launch new products that lead the fashion trend, to provide customers with quality products and services.